The Soil Pro Shredder / Screener Topsoil Machines

Specifications

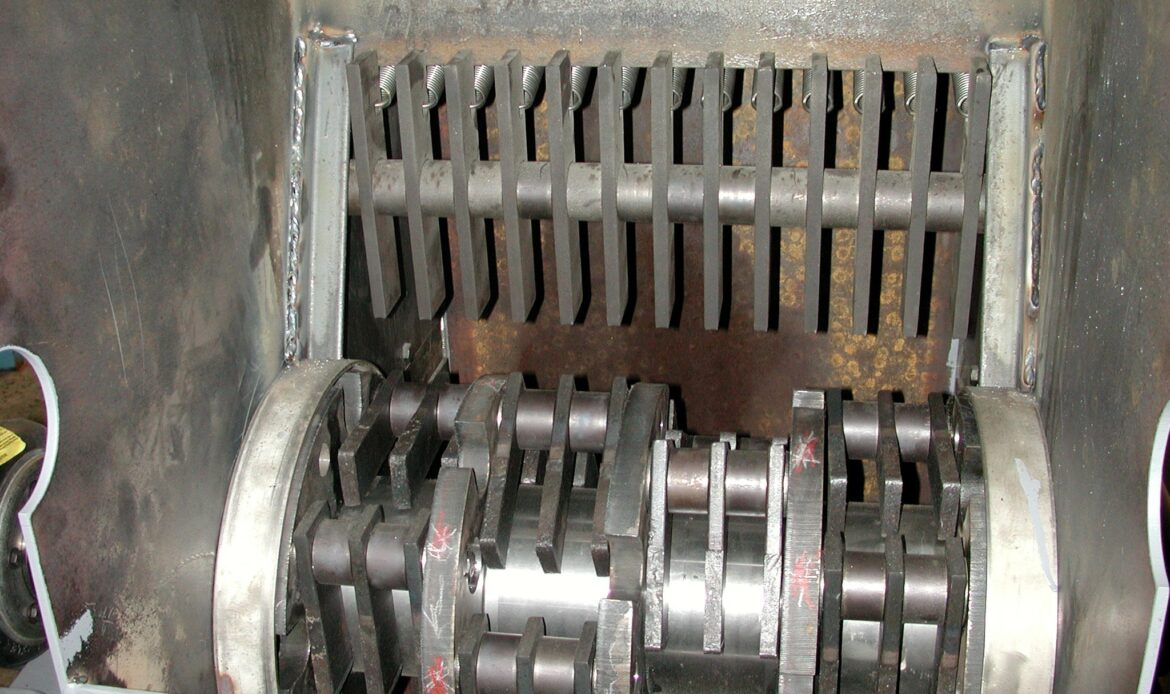

The main hammer mill rotor for the pulverizer takes its power directly from the output shaft of the power unit. This ensures that full power is available at the hammer mill rotor at all times. We do not power the main rotor with hydraulic power, because the response time under load is too slow and the power obtained is too weak for heavy duty grinding in heavy soils.

Our infeed and exit conveyors are hydraulically powered and are, therefore, adjustable according to the moisture content of your dirt. We also power the upper rotor hydraulically and have the option to power the screen basket either mechanically or hydraulically. These features allow you to adjust to daily changes in conditions and work materials that otherwise would have to be let go for another day.

Additionally, our shredder chamber is made from ½” thick armor plate steel. The original Lindig machines had ¼” mild steel. The components in the hammer mill assembly and the upper rotors are made from very high hardness and very wear resistant materials and are more durable than the conventional steels of other manufacturers. Structurally, the fabrication of the rest of the machine is heavier and more durable than most other machines on the market. We are using ½” wall 6″ x 4″ tubing for the frame; C10 15.3 lbs/ft² for the exit conveyor channel; 12 ga sheet and 2″ square x ¼” wall tube for the sheet and framing of the feed hopper.

Virtually every aspect of this line of machinery has been made to last. And these standards we know to be higher than any other maker of this kind of machinery. We are proud of our attention to quality and want you to be exceptionally pleased with purchase of one of our machines.